Plastic substitution brings massive growth potential to competitive fibre-based packaging

The global environmental crisis, including climate change, waste pollution, and environmental degradation need dramatic and fast reaction and a major paradigm shift in consumption. Fibre-based substitution of plastic packaging is one of the solutions the bioproducts industry can offer.

Selection of sustainable solutions

Companies are fiercely seeking novel solutions to improve the overall sustainability of their product portfolio. In fast moving consumer goods (FMCG), packaging often stands for a minor share of the product’s footprint but has an important role in product protection and brand image. Moreover, plastic packaging accounts for nearly two-thirds of post-consumer plastic waste, causing reputational, and environmental, damage when found in places where it does not belong. Hence, inaction has become a massive business risk.

Solutions are multifaceted and require both cross-industrial and -institutional collaboration as well as a new level of adaptiveness from consumers. Firstly, consumption needs to be significantly reduced. This implies, for example clever and snugger fitting packaging design, reduction of multilayer solutions, and reusable packaging. Secondly, the properties of plastic need improvement. Above all, major investment in plastic recycling and harmonisation of polymers is required. The growing use of biobased- and biodegradable plastics can, on a small scale, tackle problems of waste accumulation while leaving fossils in the ground. Thirdly comes material substitution.

Substitution potential is substantial

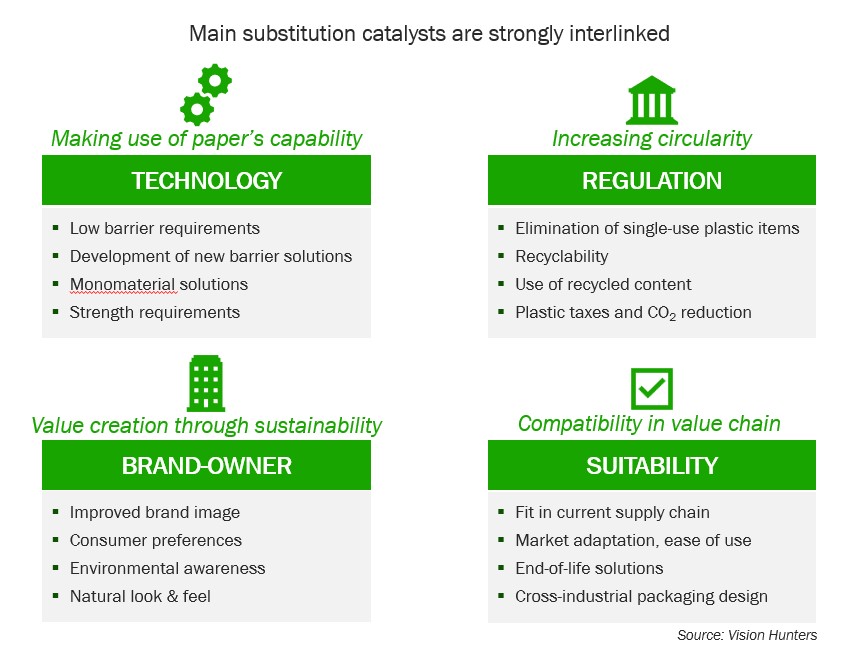

Well-functioning substituting fibre-based solutions exist in a wide range of packaging end-uses. Overall, fibre-based solutions perform best in end-uses where paper’s natural capabilities are strongest, that is where barrier and strength requirements are moderate. This range widens constantly alongside the development of new barrier solutions and improvements to strength properties of paper.

Material substitution is also heavily influenced by regulation. In the EU, increasing circularity is the cornerstone for developing the legal framework. Major drivers boosting fibre-based plastic substitution has been the single-use-plastic directive, requirements regarding recyclability of products including extended producer responsibility (EPR) schemes, and decarbonisation. Plastic taxes, so far imposed by individual member states, can also become a significant tool, if the material cost can be converged as result.

While ambitious regulation creates incentives for technological development and as a consequence new substituting solutions, the consumer’s role in a strongly B2C focused business such as packing should not be overlooked. Increased environmental awareness has started to be noted in consumer choices and demands towards brand-owners. It is no longer sufficient to be sustainability compliant. Operating actively in the frontline of innovation and investing in carbon footprint reduction throughout the value chain is imperative for a brand’s long-term value creation and existence.

Untapping the volume potential needs ambition and commitment

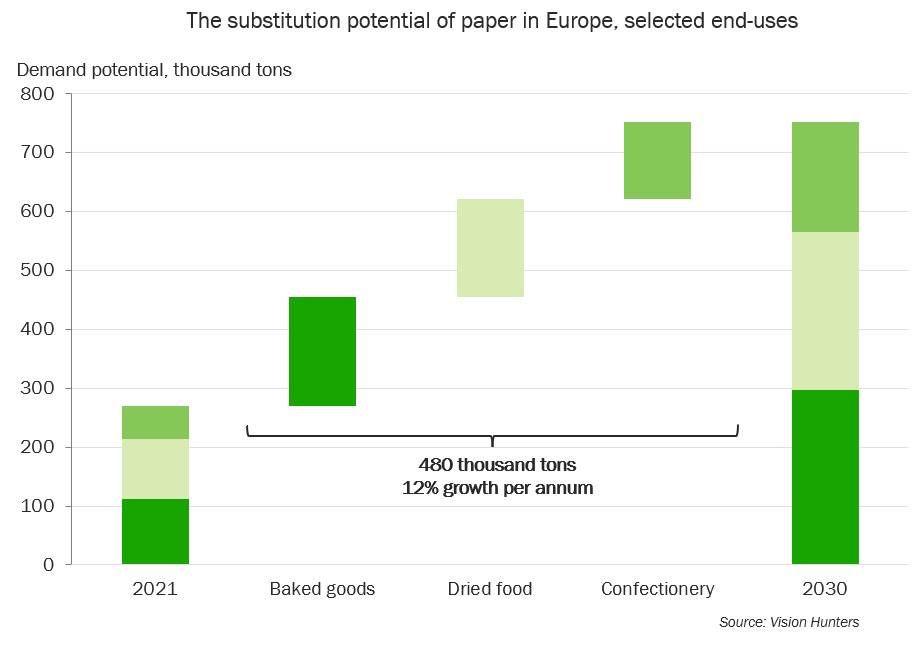

Even in an optimistic scenario, it is realistic that only a fraction of today’s plastic packaging volume is replaced by fibre-based alternatives. However, taken the magnitude of the market, this translates in a massive potential for the paper and board industry.

The higher unit weight of fibre-based packaging further adds to the volumes generated through substitution. According to Vision Hunters’ calculations, this can be witnessed as yearly growth rates of up to some 20% in Europe for specific grades and end-uses. The potential is immediate and unprecedented in size for example in grades like carton board, moulded fibre, and various packaging papers.

However, various risks and uncertainties prevail, while untapping the full potential requires lack of drawbacks or delays in ambition level, and significant effort from producers to introduce well-functioning paper-based alternatives at a sufficient speed.

Plastic’s strength-to-weight ratio and width of natural barrier properties will be hard to beat.

Notwithstanding, a fossil-free, renewable and certified raw material with existing easy and efficient recycling infrastructure, and a fast break-down time if ending up in nature, can have a central role in solving the environmental crisis, one packaging at a time.

On the author: Iris Ollilla, Project Manager, is an environmental economist by training. Iris has conducted multiple strategic assignments, focusing on market, portfolio, and financial analysis.

Vision Hunters provides strategic advisory services for the forest and bio-based industries, and energy sectors. We assist leadership teams in making the smartest strategic choices to improve the outcome of their company in the future. We are highly experienced and result-oriented and have advised many of the leading companies in our industry.