Future pulp mills are a hub for biobased industry solutions

Future pulp mills enable improved circularity and may act as a platform for external companies working in a bioecosystem. Sustainability drives continuous technological advancement and contributes to resource efficiency and the industry’s economic competitiveness in the long run. In future pulp mills, energy and resource efficiency are key aspects of design criteria and all side-streams are utilized according to principles of circular economy. The advancement is sped up by digitalisation, advanced process controls, and improved measurements leading towards autonomous mill.

Pulp mills are significant energy producers

Pulp mills may also contribute to the energy crisis by generating renewable power to the grid and providing district heating to local communities. A modern pulp mill may achieve up to 250% electricity self-sufficiency and sell renewable electricity to the grid. For example, in the case of the Kemi bioproduct mill, which is scheduled to start-up in Q3/2023, the share of produced electricity amounts to around 2.5% of total energy produced in Finland.

Modern pulp mills help to stabilise the electrical grid since they produce electricity continuously and are not affected by weather conditions, unlike wind and solar power.

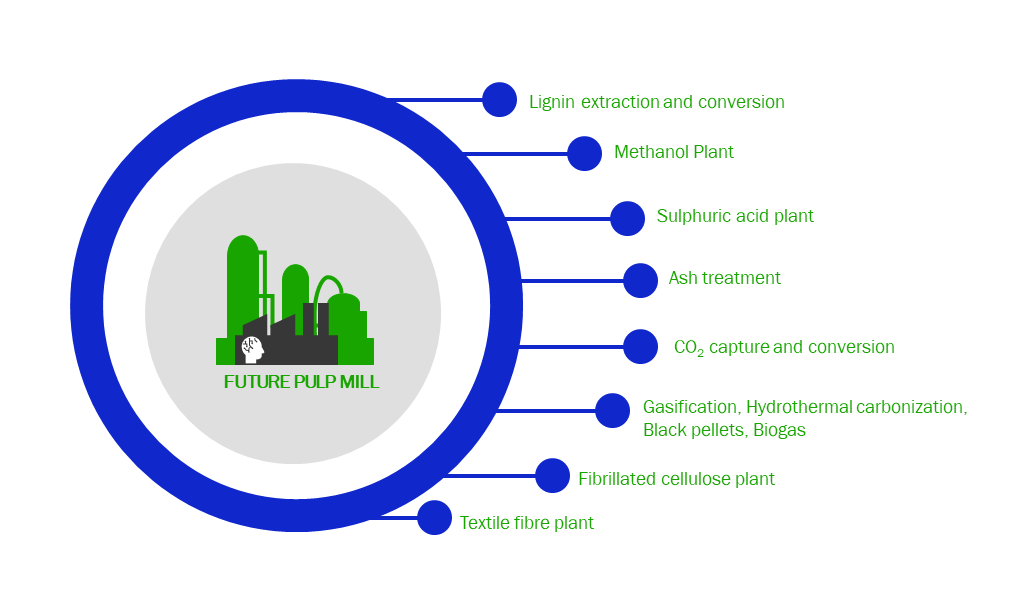

Future pulp mills will have more departments/plants that use all streams, as well as possible external operators, all on the same mill site. New plants can purify and produce chemicals like methanol and sulfuric acid. There is no single solution for the mill, but rather a range of options in both the core mill and operating within the ecosystem. External operators might utilize the existing infrastructure available on-site such as energy or effluent treatment.

Figure 1:Future pulp mills enable improved circularity and may act as a platform for external companies working in a bioecosystem.

Figure 1:Future pulp mills enable improved circularity and may act as a platform for external companies working in a bioecosystem.

Side stream utilisation will further increase

Typically, the side streams to be utilised consist of tall oil, turpentine, and lignin. Turpentine has been utilised in a vast array of chemical industry applications, and tall oil has been used for biodiesel production for years.

Novel, high-value uses for lignin are undergoing commercialisation and are under active research. Simultaneously, lignin extraction debottlenecks the recovery cycle. New products, technological development and innovation enable sustainable improvement and higher value creation throughout the value chain.

Cheap renewable fuels such as forest residues are becoming scarce in Europe when more advanced biofuels are costly and not widely available. Alternative feedstocks can be found from waste streams. Converting sludge waste to higher value biofuels, can provide alternatives to replace solid fossil fuels such as coal or peat. There are thermochemical processes that increase the heating value and storability of sludge. Storability is especially important to cover seasonal variance in energy consumption when peak consumptions occur during wintertime.

Energy efficiency and decarbonisation

Biofuels allow mills to run without the need of fossil fuels. Typical major source of CO2 emissions, the lime kiln, can be switched to using biofuels, such as syngas from bark gasification. Energy efficiency is a key aspect in modern mills and new solutions for electrification, heat recovery & upgrade, secondary heat utilization are being applied. Opportunities for optimization still lie in water intensive unit operations such as drying and evaporation processes.

In the future, pulp mills also have potential in utilizing green hydrogen once the technological gap has been overcome for electrolyser capacity and green electricity need and availability. Also CCU technologies are interesting for pulp mills since the released CO2 is biogenic. CO2 can be used for example in production of methanol. Nevertheless, cross industrial actions are needed to make implementation of new innovations feasible.

On the author: Anna Nuotio Jarret, Project Manager. With an M.Sc. in Technology, Anna has practical expertise in the pulp and paper sector, covering all project stages from early feasibility assessments to basic and detail engineering projects in investments ranging from mega-sized investments to strategic techno-economic studies.

Vision Hunters provides strategic advisory services for the forest and bio-based industries, and energy sectors. We assist leadership teams in making the smartest strategic choices to improve the outcome of their company in the future. We are highly experienced and result-oriented and have advised many of the leading companies in our industry.